© istockphoto.com / Mailson Pignata

Process Plant Engineering

Chemical plants from FEED and process design through to detailed engineering

Contact:

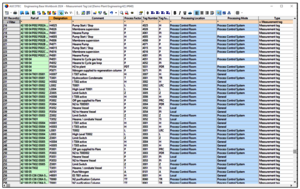

During FEED or basic engineering, Engineering Base enables the direct import of simulation data, not just from tools such as Aspentech and Pro II, but also via Excel or XML. The data can be compared automatically and can be used directly for further developing the actual plant concept that is finally chosen. Service providers are therefore able to 'afford' far more scenarios and save time. The result: concepts of superior quality and an advantage over the competition.

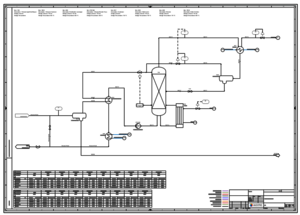

With Engineering Base, you can quickly and easily create all the main diagrams, such as process flow diagrams (PFD) and P&IDs, on the basis of standard shapes using the built-in MS Visio software. All disciplines can work on the same object and present it appropriately in the respective diagrams. As these are merely different representations of a single instance of this object in the central data model, absolute consistency is guaranteed.

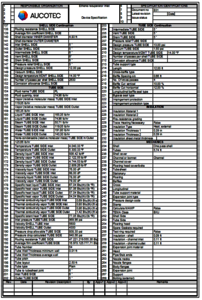

Engineering Base makes light work of creating lists and data sheets for the various disciplines. "Asset 360" automatically performs this work instantly using the digital plant twin generated in Engineering Base as a basis. Whether it's balance sheets, mass flow tables, design data sheets or lists of instruments, rooms or anything else – once the templates have been configured, you can obtain consistently completed data sheets for each of your assets with the greatest of ease.

The main components are designed in the FEED phase. Engineering Base provides reusable templates for this purpose, to which additional, project-specific data is then added. The design is based on the import of calculation results from upstream software tools. This allows you to create the objects for the main components at an early stage and then continuously work on their detailed design without system discontinuities over the course of the project.

The FEED phase is also used to carry out initial EI&C estimates and design work – from high-voltage circuits and hook-ups to identifying long-lead components and the first logic diagrams. The basic data created centrally in Engineering Base is always kept consistent and is fine-tuned over the subsequent engineering phases. This puts an end to the need to perform data maintenance elsewhere.