Centralized engineering for satellite wiring

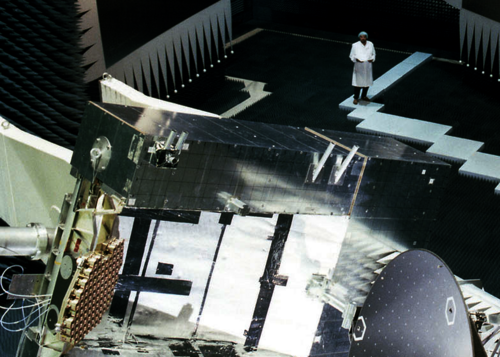

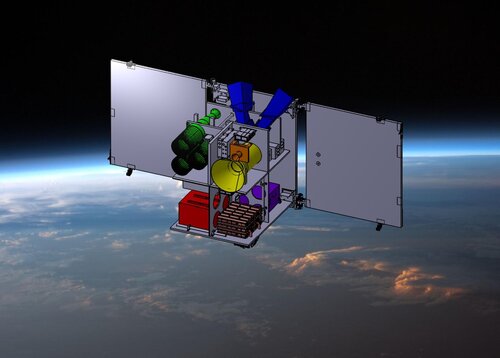

OHB System AG is one of the three leading space companies in Europe. It specializes in high-tech solutions for space, science and industry, with low-orbiting and geostationary satellites representing its core business. The company now relies on Engineering Base to help it plan the wiring harnesses for these satellites. After all, this type of harness design application requires completely reliable and consistent data at all times, making it an ideal use case for the cooperative engineering platform.

How to ensure data consistency of the highest standard

Engineering Base Cable maps the entire spectrum of conventional systems engineering tasks – from definition of the systems, through design of the physical infrastructure and specification of the wiring information, to detailed design of the finished wiring harness. And it does so using the latest data at all times. There is no need for duplicate entries and transmission errors are a thing of the past. What is more, the digital twins of the harnesses are created at the same time.

Model-based systems engineering not only improves planning processes, but also documentation and design reliability. "Only a data model open to everyone involved allows simultaneous, collaborative engineering across different disciplines, locations and even system boundaries," explains Georg Hiebl. "This means that changes now only need to be applied once." The openness of Engineering Base allows 3D data along with ERP and other third-party systems to be closely linked to the engineering process.

"Our customers in the aerospace industry usually proceed according to the V-model. Engineering Base Cable provides optimum support for this. Specifications from the early project phase can be compared against later, more detailed phases and validated. Engineering Base Cable also provides the data required for testing. This makes the whole process highly efficient and ensures high quality."

Djibi Dia, General Manager in France