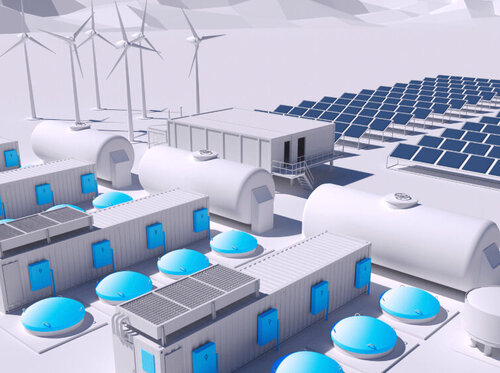

Green Energy

Decarbonization through solar, wind, hydropower and hydrogen technologies

Contact:

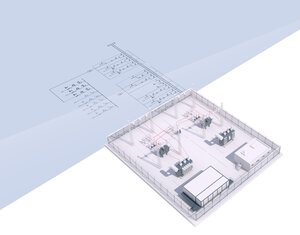

Engineering Base PTD enables convenient, consistent-at-all-times planning of all aspects of a power distribution infrastructure across all voltage levels.

Engineering Base brings together the developers of primary and secondary equipment as well as protection and control technology in a single, universal data model. This puts an end to the manual and delayed exchange of information between different systems and platforms.

The expert network for digital planning, construction and operation of objects has already helped to get many standards for the construction industry off the ground, including the BIM data format IFC. As a member of buildingSMART Deutschland, AUCOTEC is actively involved in the development and harmonization of norms and standards.

Engineering Base PTD makes it possible to implement the exacting requirements of standard IEC 81346 efficiently and consistently. Engineering Base maps the three independent views "Product", "Function" and "Location" in standardized form and fully supports further standard-compliant project planning. In this way, standardization also generates benefits for the engineering side.

Aucotec has carried out some pioneering work by becoming the first company in the world to integrate the control technology definition as per IEC 61850 directly into Engineering Base in standardized form. The cooperation platform makes it possible to map a substation's entire life cycle – from project idea and detailed planning through to construction and finally maintenance – in a piece of software, thereby bridging the divide between the worlds of hardware and software, i.e. between secondary equipment and control technology.

The Project Builder makes plant configuration much easier for planning professionals. This built-in Engineering Base tool is an extension of the Advanced Typical Manager (ATM), which can be used to define cross-disciplinary, function-oriented modules. The Project Builder can be configured for each plant type with the help of conditions and rules, meaning it has the necessary know-how on the "right" typicals for defined projects. And it is familiar with the components of the ATM modules, so it automatically knows which one fits where. This saves time and improves data quality. What's more, specialist knowledge about the existing typicals is no longer required.