Energy & Infrastructure Technology

Contact:

The central data model in Engineering Base acts as a single source of truth, enabling cross-disciplinary plant development from the initial idea through to the finest details. There is only one instance of each object in the model; diagrams, data sheets and lists are merely different representations of the same object. All specialist departments edit the objects and add further details as required from their perspective, with each addition immediately visible to everyone else – no interfaces, no data transfers, no transmission errors.

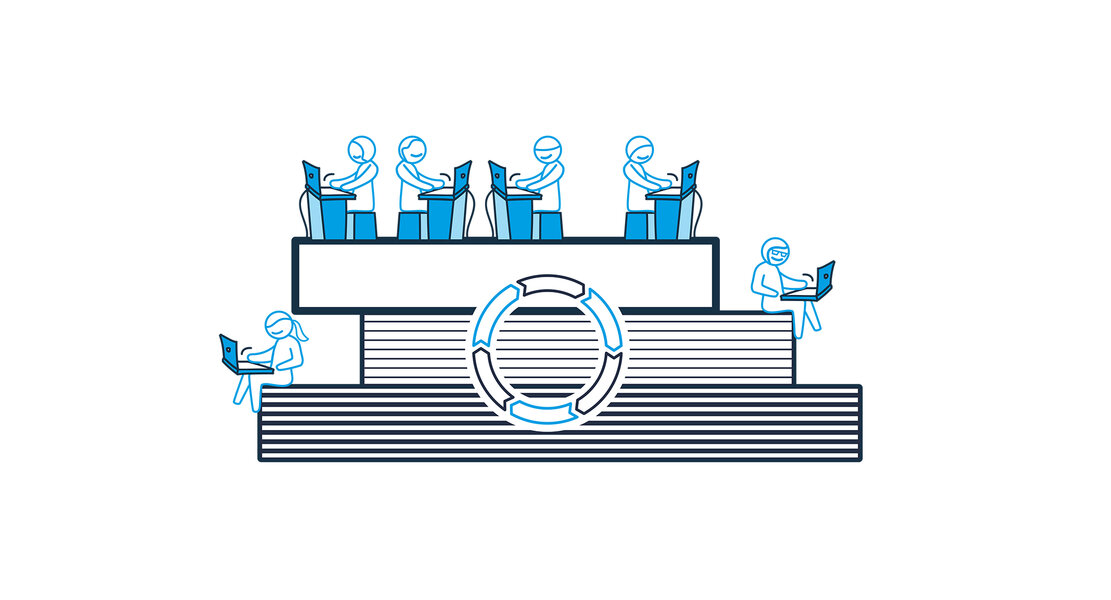

Modular design and interdisciplinary teamwork are the two key elements for more efficient engineering. Both are core strengths of Engineering Base. Using the universal data model as a basis, the platform supports modularity at all levels. It's all about intelligent reuse – from object templates and the central component catalogs through "working from a modular kit" with the Typical Manager to "configuring rather than designing" with the Project Builder. The complete transparency of Engineering Base and having the digital twin as the single source of truth also opens up brand new scope for teamwork. The traditional cascade model gives way to a parallel and agile form of working. With Engineering Base on board, you can achieve new levels of efficiency when it comes to cooperation.

Integration into a company’s IT landscape and therefore its essential business processes makes the complete digital twin a particularly profitable resource. Simulation and calculation tools are embedded in the engineering itself in such a way that they always work with current data and their results enrich the digital twin. 3D systems for mechanical design are always kept up to date, material data is synchronized with ERP and PLM, and the results of the engineering are in turn automatically transferred as bills of material and documents. Engineering Base both enables and facilitates all of this with its exceptionally open architecture. Here again, efficiency comes built in, along with data consistency and integrity.

The digital twin (with its flexible and extendable data model), support for cooperative team engineering and openness for integration and processes offered by Engineering Base are ideal for applications across an extremely wide range of industries.

From large-scale plant systems in the process industry via full plant and mechanical engineering – including automation and power distribution – to mobile systems: they can all benefit from the capabilities of Engineering Base. Additional features, such as guidelines, templates and assistants, make industry-specific tasks that much easier.

Find out more about how Engineering Base can make a difference in your industry: