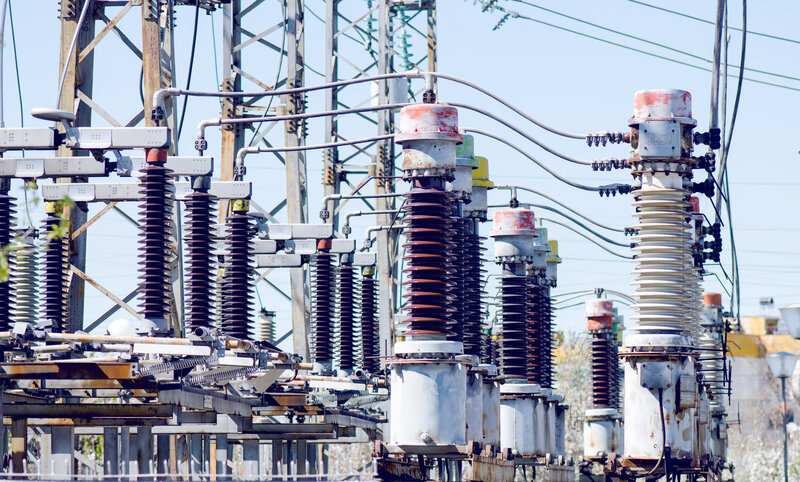

Engineering expertise in plant modeling speeds up expansion of grid

Braunschweiger Netz GmbH (BS|NETZ) is not only responsible for thousands of miles of local electricity, gas, district heating and water supply grids and networks, as well as the associated plants and their further development – its engineering team also helps other grid operators in Germany, Austria and Switzerland to take their plant documentation to the next level by digitizing it. BS|NETZ develops its own engineering and third-party orders using AUCOTEC's data-centric Engineering Base platform. The company’s main reason for choosing the software was its ability to build and maintain a consistent and centralized cross-disciplinary data model that also complies with international standards, covering everything from the large items of primary equipment in the field to the smallest control cabinet terminal, as well as all the automation.

"Engineering Base lets us carry out object-oriented mapping of our substations in the digital world. This creates a digital twin that makes it possible to link the same objects in different disciplines and systems, such as 2D and 3D engineering or ERP."

Michael Wedde, Group Manager "Digital Plants" at BS|NETZ

Learn more

© Braunschweiger Netz GmbH

AUCOTEC and the energy industry

AUCOTEC has been developing software for the energy sector for over 30 years. For a long time now, the PTD working group initiated and overseen by AUCOTEC has been working together with customers and partners – all experienced energy experts – to drive innovation and develop guidelines that have been adopted as standards in Germany. All this experience and practice-oriented thinking has been invested in our Engineering Base platform. The software content demonstrates this to impressive effect, as do the many best-practice examples from around the world. Engineering Base thereby helps engineering projects to advance, while also bringing us closer to the sustainable future so crucial to us all. Time is not just money here; it also affects future quality of life for everyone.

From the initial project idea through to plant operation, our Engineering Base platform provides a foundation for greater sustainability and lower operating costs. This is because it offers more than just a snapshot of a plant under construction or in operation. The digital twin in Engineering Base is 'born' long before the real-life, physical twin. Its data model forms the basis for the planning and development work carried out by all the engineering disciplines involved, as well as for the construction and finally the operation of the plant, because it evolves with the plant and therefore always reflects its current as-built status. This highly digitized documentation is therefore always the root or center of all knowledge about the plant. Its inestimable value, the cumulative result of vast amounts of expertise, is retained throughout the plant's entire life cycle.

All areas of engineering – from primary and secondary equipment to protection and control technology – have access to this single source of truth; any further, discipline-specific detailing is immediately visible to all other specialists and can continue to be processed directly. Waiting, liaising and searching are no longer; everyone works together, cooperatively and in parallel on the same model. Consistent data validity is achieved very easily in this way – without any duplicate entries or manual data transfers, and therefore without the error-fixing and extra work these require.

"Engineering Base lays the foundations for tackling the challenge of power distribution in the future. It is the single source of truth for primary and secondary equipment as well as for protection and control technology, and ensures exceptional consistency along with a more efficient, more reliable form of working. The cooperation platform maps the complete life cycle of digital substations and enables seamless engineering."

Michaela Imbusch, Product Manager - PTD