ERP

- SAP

Contact:

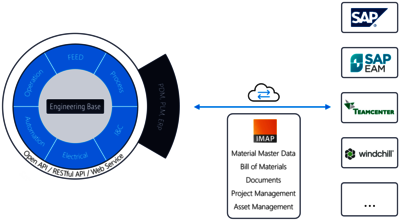

That is the approach we take to integration. Consequently, our powerful Web API can be integrated with our partners' middleware very easily. What is more, the connection evolves just as easily with every new version of a third-party system. This halves the work involved, not just with integration, but maintenance too. The easy-to-connect, open architecture therefore plays a key role in completing your integration project successfully on time and on budget.

The flow of data between EB and ERP/PLM systems forms the basis for genuine team play between engineering and data warehouse. Master data harmonization can take place either on demand, with a rules-based approach or periodically. In this way, everyone involved is able to view and use the latest data update, covering everything from availability to technical details. This also applies for highly complex, structured materials.

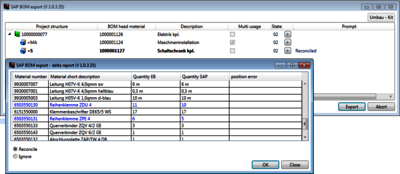

Engineering Base enables cross-system transfer, synchronization, creation and delta management of BOMs. No matter whether it's a quantity or single-level BOM, a multi-level BOM or an overview focusing on functional aspects, they are transferred to ERP and PLM solutions smoothly, fully automatically and in real time, resulting in error-free ordering processes.

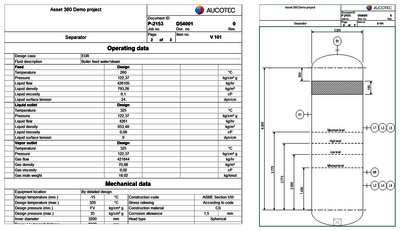

A sophisticated system of document management allows immutable PDF documents to be created, stored and accessed for legally effective documentation of technical specifications. These documents can be created or updated in Engineering Base with unique version numbers and ensure binding transparency for suppliers and other contacts.

On the asset management side, Engineering Base offers bidirectional synchronization with inventory management. This link-up allows managers to track values – either functional assets or functional locations – across systems. The built-in delta management and an optional release module provide certainty and transparency in the event of extensive asset changes ("maintenance", as it is known).

Engineering Base simplifies management of engineering projects. Workflows can be imported from third-party systems, including BOMs (BOM headers) and documents (doc numbers), or easily defined as set processes using the built-in workflow wizard – including rights management, assignment of task packages, and status feedback to connected ERP and PLM systems.