Benefits in brief:

- Closed data flow from the flow chart to the material number for the ERP

- Greater security of communication and project overview

- No multiple data entries, no change maintenance, fewer errors

- Improved consistency accelerates binding tendering

Change is a constant companion in the engineering of machinery and plants. In the overall product design and development process in which numerous different disciplines and systems are usually involved, the manual revision of changed data in lists, drawings and 3-D models is not only associated with a significant effort, but also with the increased risk of inconsistencies arising within the data. They are often detected far too late because it is almost impossible to maintain an overview of the generally high level of data complexity.

Thus it is not only the correction of errors, but also the search for errors that wastes a lot of valuable time. This can result in system downtime in addition to losses in the quality of data and documentation.

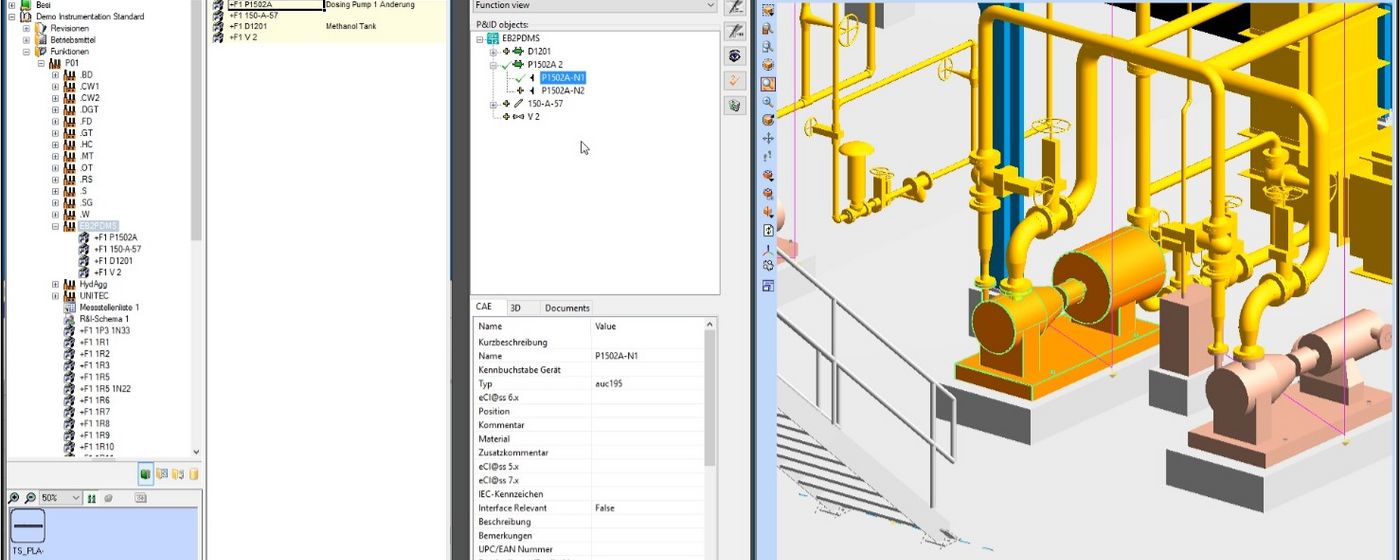

With automated bidirectional exchange of data between the different systems, the design process is significantly accelerated, and the quality of documentation also benefits from the considerably improved data consistency. Such a connection is enabled by the AVEVA 3D Plant Connector between AUCOTEC's cooperative platform Engineering Base (EB) and AVEVA EVERYTHING3D (E3D), PDMS and Marine, the powerful tools for planning, design, engineering and management of buildings and infrastructure.

If both systems are used in a project, the data developed in them can be automatically exchanged, both quickly and consistently, via the AVEVA 3D Plant Connector.

Through the process chain that is closed by the connector, information flows automatically from the P&ID via 3-D into the PLM/ERP system and guarantees the consistency of the data.

This enables, for example, the equipment, containers, instruments, loads, pumps or fittings that are planned in the P&ID using EB to be linked to the corresponding 3-D objects in the AVEVA system.

As well as the properties of the items, the structuring of those items is also transferred. Thus all the relevant information is made available in both systems without additional manual effort.

Once the items in EB have been linked to those in 3-D, changes are automatically transferred from one system to the other.

Using the integrated navigation function, the user can navigate directly from the display of an item in one system to the display of that item in the other system. A zoom function also enables the convenient detail view of any selected item.

Files (e.g. 3-D models) that are inserted into or linked to an item in EB may be directly retrieved or positioned in the 3-D system, which immediately links the items together.

AVEVA E3D Plant Connector

AVEVA E3D Plant ConnectorThe automated topology test is a special highlight. Piping and instrumentation data from the 2-D P&I diagram is compared with the 3-D model and checked for differences. The user receives a clear list of differences for editing purposes.

Topology check

Topology checkThrough integrated engineering - from the flow chart via the 3-D model to the bill of material (BOM) with feedback of the material number into the PLM/ERP - the data loop is closed and synergy is created.

All employees involved in the process, regardless of their location or area of specialization, can communicate significantly more securely and obtain a far better overview of the up-to-date design status.

Multiple entries and time-consuming and error-prone maintenance of changes are eliminated.

The cross-disciplinary consistency of data prevents errors in reconciliation, quotations can hence be issued more quickly and with a higher level of confidence.

The solution described here represents the full scope of our standard solution. Of course, it can be extended in terms of functionality for adaptation to specific requirements. In addition to AVEVA EVERYTHING3D (E3D), PDMS and Marine, AUCOTEC integrations are also available with a range of other 3-D programs.