As the heart of every vehicle, the EDS (Electrical Distribution System) is a 'Hidden Champion‘. Although it does not play a role in the purchase decision and the trend is clearly moving in the direction of software-defined vehicles, it remains the lifeline of every vehicle. The demands on its development processes and quality are even set to increase, not least because of the functional safety required by the development of autonomous driving. However, missing or only scattered data relating to the EDS slow down the overall vehicle development and its quality enormously.

With the possibilities of the EDS Design Center of the Engineering Base (EB) cooperation platform, AUCOTEC aims at consistent digitalization of the on-board power supply development. It generates significant time and cost savings by building a digital object model in just a few clicks, which in turn is the basis for analyses and simulation support.

Analyses need data

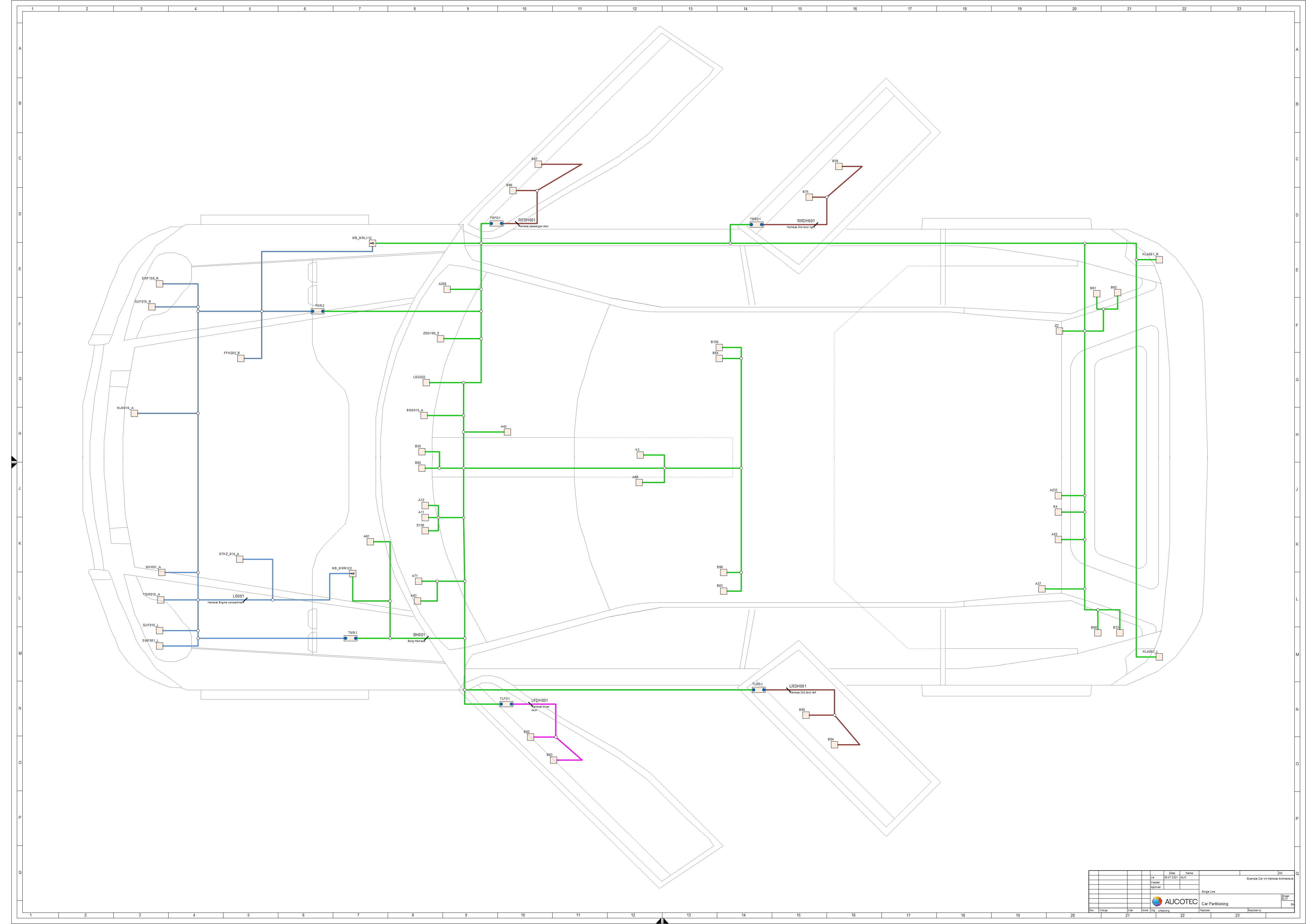

© AUCOTEC AG

© AUCOTEC AGData basis for the EDS Design Center: harness architecture defined in Engineering Base with components and inline connection points

The prerequisite for this is EB's central data model of the on-board power supply, which grows continuously from the initial component and signal definition to the vehicle configuration and the manufacturing information and always keeps all the relevant data together throughout. It is only thanks to this database – in contrast to purely graphical on-board power supply documentation – that it is possible to analyze and calculate various scenarios, for example for weight and placement optimization. For example, the isolation point assignment for the wiring can be optimized by simulation.

Digital twin as if by magic

The whole thing is rule-based, each company being able to define its own parameters in addition to some basic rules that EB already provides. Once they have been defined in EB, the Design Center supports the on-board power supply professionals with additional capabilities: Since it is aware of all the components, signals and connections created, including their interrelationships in the EDS, it automatically selects the most suitable wire for routing. This means that all the data required for subsequent documents is generated in the model, i.e. the digital on-board power supply twin. Circuit diagrams and the 2D harness drawing can be derived from them virtually in an instant – with tested wiring that is also optimized in terms of cost.

Waiting times and misunderstandings are a thing of the past

Those who work with conventional, drawing-oriented tools usually have to draw a large number of circuit diagrams manually and define the wiring in them, without him or her being able to overlook the geometry. Therefore, this approach makes it extremely laborious, if not impossible, to define the optimal wiring. This also takes an enormous amount of time because of the inevitable queries and changes by the various experts involved in the EDS development process. With EB, on the other hand, waiting times, coordination and misunderstandings are a thing of the past, because everyone works on the same model and details it with their specialized knowledge. In the process, everyone sees directly what the others have developed. In this way, the EDS Design Center "knows" all on-board power supply aspects and interrelationships and thus creates the possibility for analyses and automatically generated plans.

Flexible standard

Due to the individuality of regulations and requirements at different customers, the solution offers a standard with the most important basics on the one hand and leaves room for specific adaptations on the other hand, for example for the requirements in large-scale production or for special vehicles such as in the truck and bus sector. "Customer feedback is very important to us in this regard. If we identify further commonalities from this, we will use them to gradually expand the standard," emphasizes Georg Hiebl, the product manager responsible for the mobility sector.